Online trade is booming

An increasing number of people and companies are conveniently ordering items over the internet, with straightforward delivery of the ordered items to their locations. The number of packages to be packed and transported daily to recipients by logistics service providers faces a yearly double-digit growth. Customer’s purchasing behavior and expectations are changing because of the increasing number of online platforms. More and more crucial for the buying decisions are price, availability and delivery time. Customers order when they have a need.

Shorter delivery times, right up to same-day-delivery, the reduction of delivery costs and minimum order quantities are also reducing the average number of items per order. With the reduction of the number of items per order, more and more air is transported in the used standardized boxes.

Optimise your logistics

The oversized boxes lead to challenges in the entire logistic chain from storage, sorting, transport to distribution. This causes increased costs because of storage space requirements and high need of transportation capacity.

For B2B shipments of accessories, spare parts, consumables, overnight deliveries are becoming more and more important. Required items need to be ready for dispatch, ex stock just in time. Here is where the PackOnTime® concept helps you to optimize your production and shipping processes and to increase productivity; all while ensuring environmentally friendly usage of resources.

The clever multi-item-packaging

The patented shape of the corrugated cardboard box enables securely transport of content, space-saving storage, and simple handling during sorting and stacking. The booming online market generates a higher demand for paper and corrugated cardboard packaging. Corrugated cardboard is popular because it requires, when folded, little space, and despite its relatively low weight, provides good stability and protection of the packaged goods. Corrugated cardboard is also environmentally meaningful because it is mainly manufactured from recycled paper.

Up to now, large quantities of identical boxes had to be produced to keep the cost of corrugated cardboard boxes low. Each change of the box size generates setup costs for box production, and time-consuming adjustments on the packaging machines. The consequence is a high ratio of air which must be transported, stored, and transshipped. Very often this empty space is filled with auxiliary materials such as polystyrene chips or wood wool, causing additional handling by the recipient.

Production of corrugated cardboard boxes

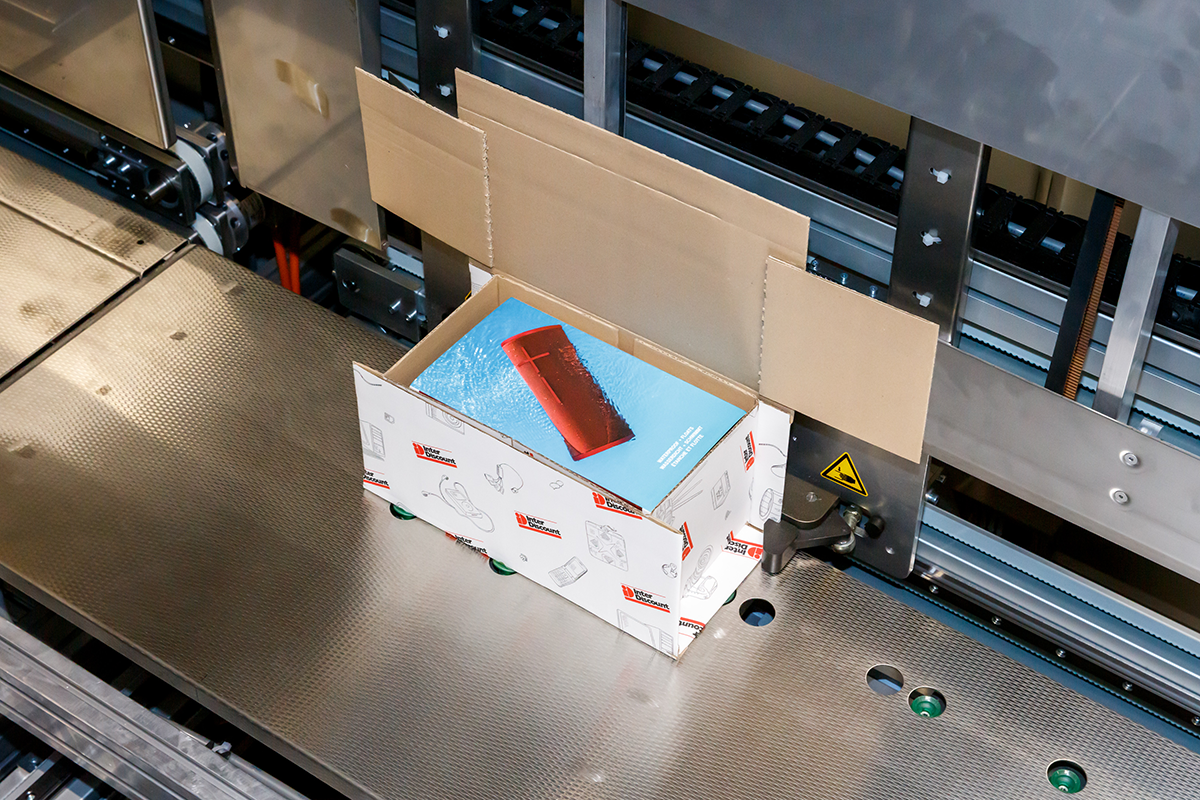

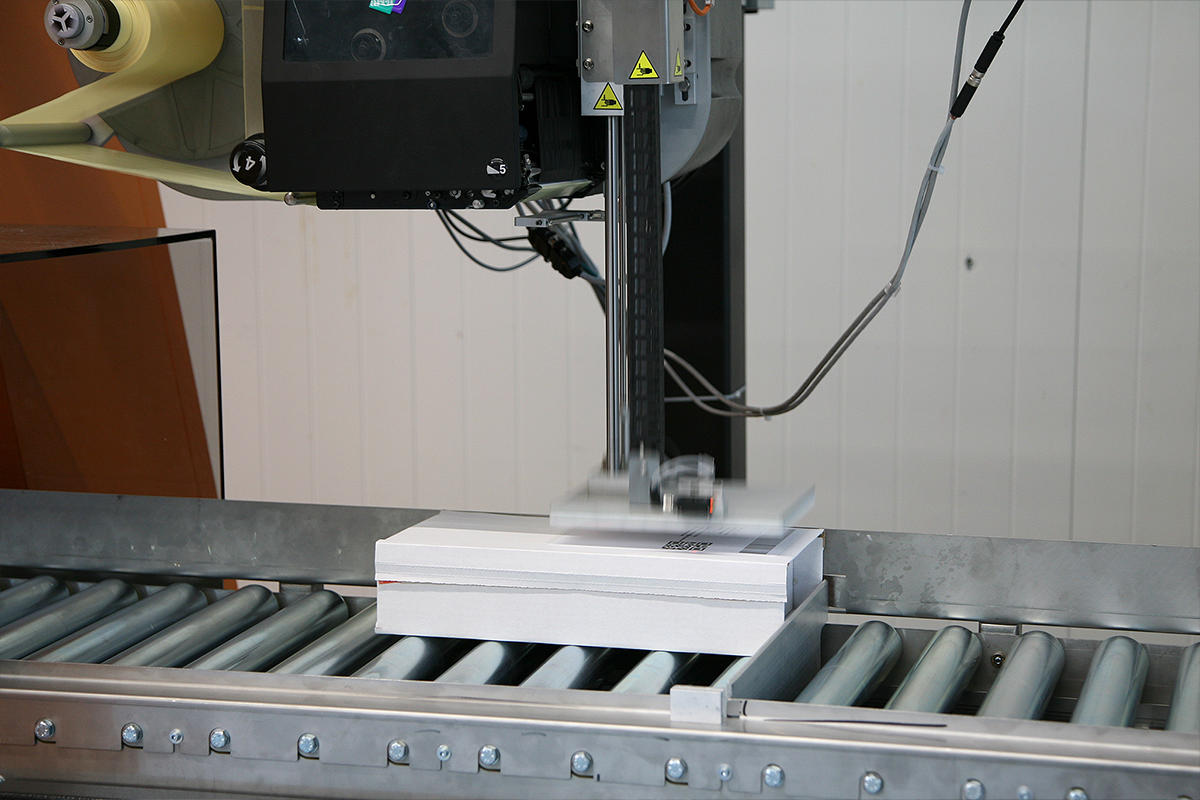

PackOnTime 2box produces boxes from corrugated cardboard sheets at the optimal size for each type of order. The goods are well protected against damage on the dispatch route, without additional filling material. To produce the appropriate box size, the items to be packed are measured dynamically, then automatically packed and the box sealed. The result is a significant reduction of package volume. A valuable contribution to environmental protection. Thanks to an integrated tear-off-strip the package can be opened frustration free, without any tools. The stable shape of the box allows return shipment as well as the use for storage.

When opening the package, you get an impression of high quality and the content is nicely presented. The boxes can be branded as desired by using preprinted cardboard sheets, or by adding a digital printer. The use of corrugated cardboard sheets allows fast and simple changeover between various cardboards.

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Kern system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

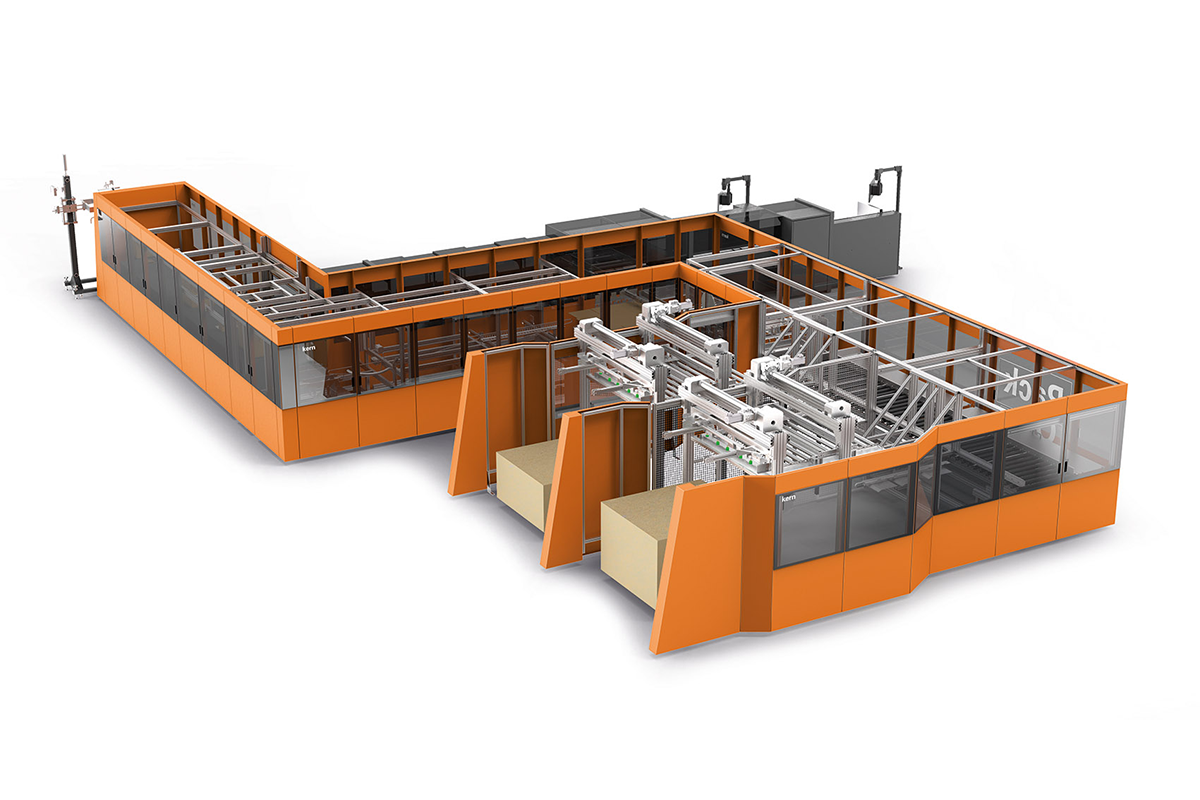

| 1. Item placement and measurement | The items are placed on a belt and fed to the system. The dimensions of the placed items are measured to determine the required box size. Depending on the requirements, the system can be equipped with multiple inserting stations. |

| 2. Corrugated cardboard sheet feeder | The box is made from corrugated cardboard sheets. Depending on the determined dimensions, the system selects the appropriate cardboard size. The system can be equipped with up to three corrugated cardboard sheet feeders according to the requirements. |

| 3. Corrugated cardboard processing | The corrugated cardboard is tailor cut in a first step then perforated and creased. The box is partially erected, glued, and transported to the items infeed station. |

| 4. Items insertion | The system conveys the items into the tailor-made box. Before closing a delivery note or invoice can be inserted into the box. |

| 5. Closing and labelling | The box is now automatically closed and sealed. Before leaving the system, the package will be provided with the corresponding shipping label. |

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you

Get in contact