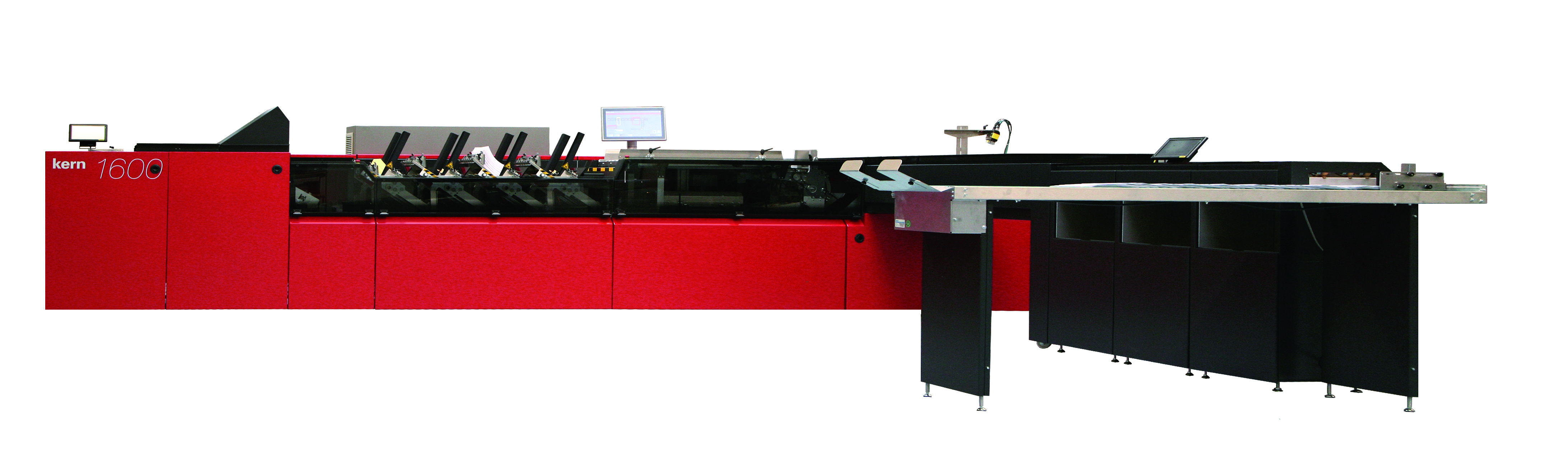

Simple and multifunctional

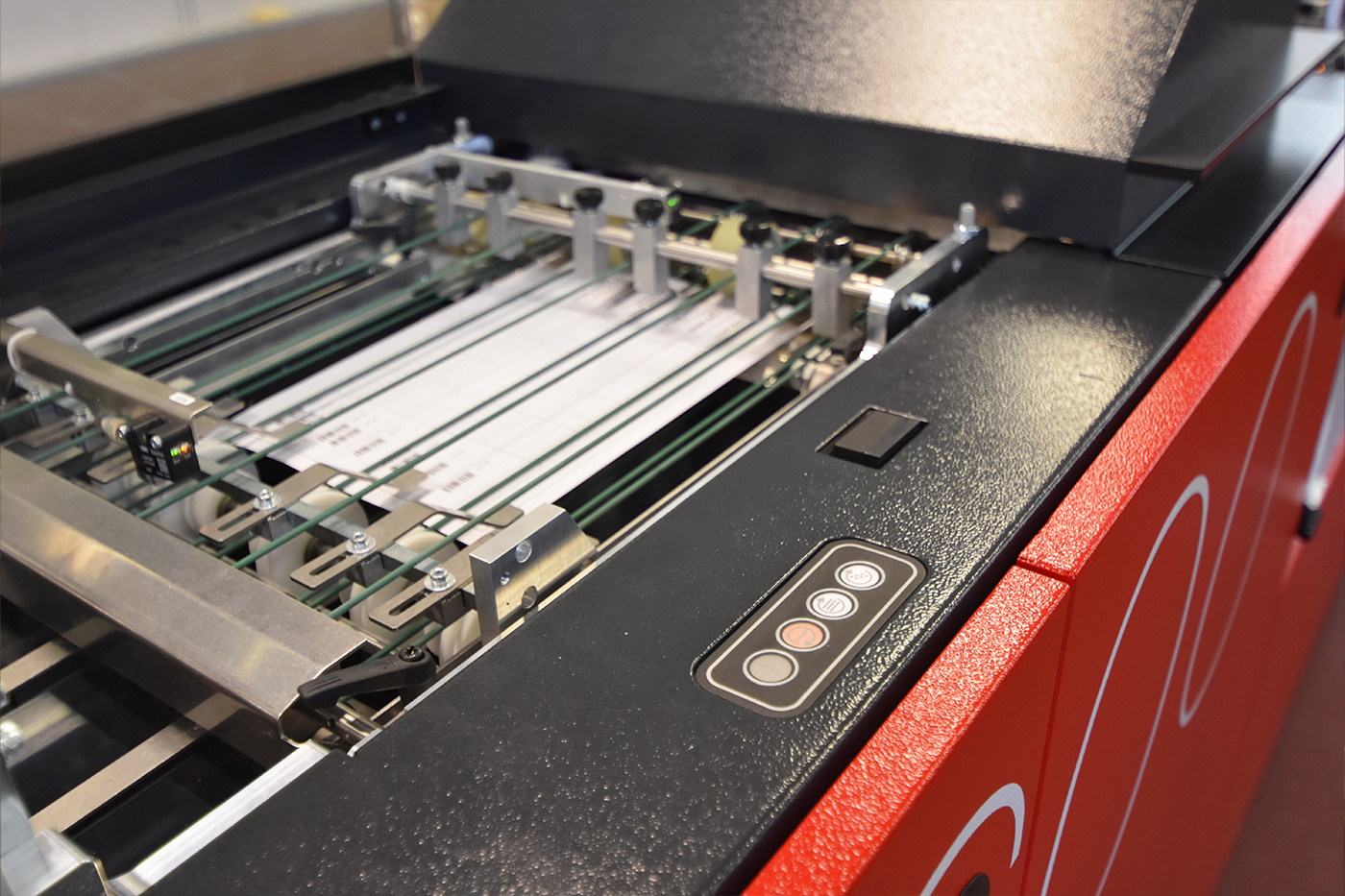

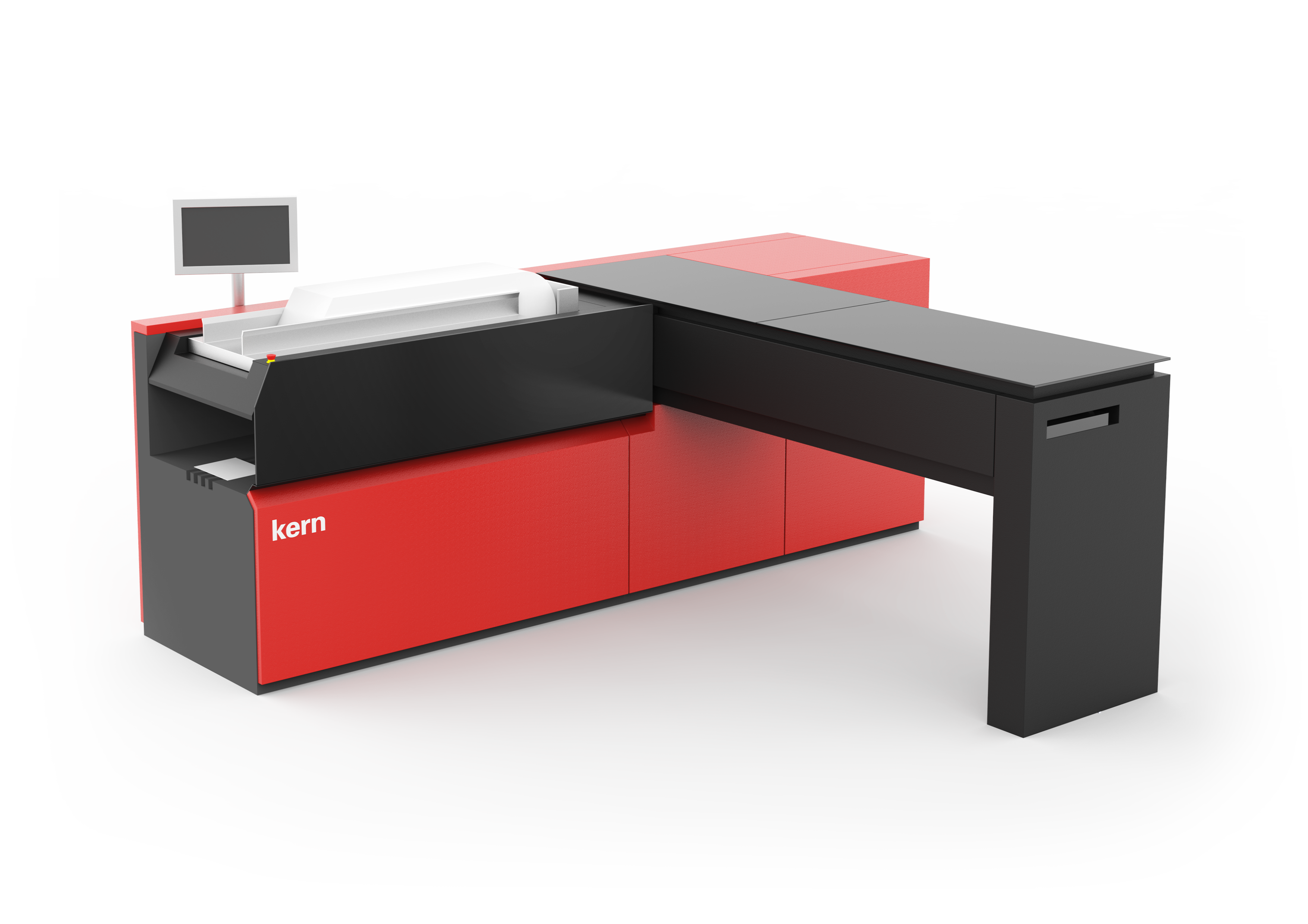

The Kern 1600 flex is characterised by high flexibility, fast changeover, maximum reliability and simple operation. It is suitable for use in the transactional and direct mail markets. The multi-format inserting system Kern 1600 flex is available for use from continuous stack/roll or cut-sheet processing. The system is particularly characterised by the fact that the ideal system configuration for the customer can be put together from a wide variety of modules. Thanks to the multi-channel capability (up to 3 channels), the system offers an enormous range of possibilities. These are also automatically compared with each other, whether single sheet or/and continuous sheet.

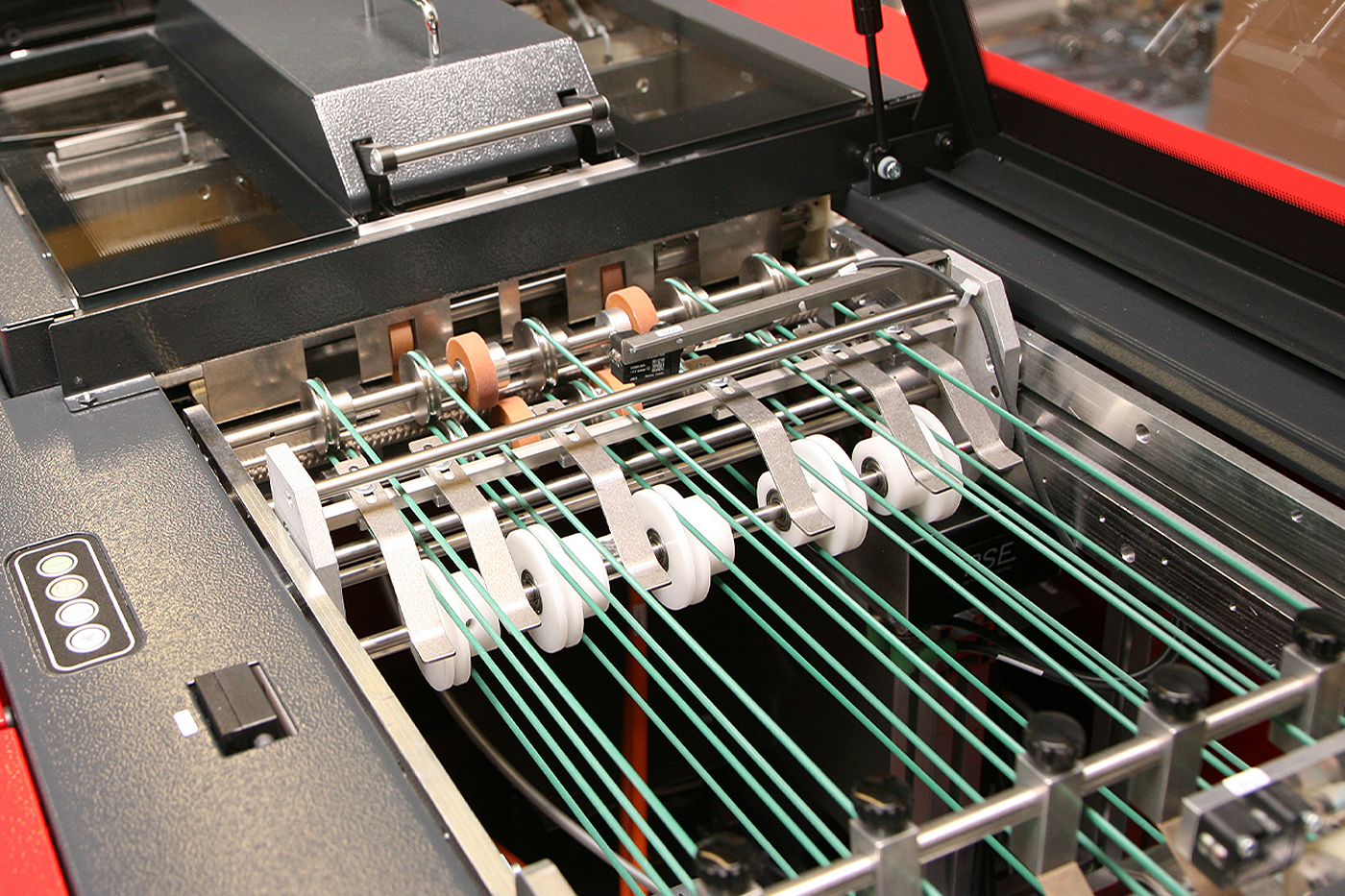

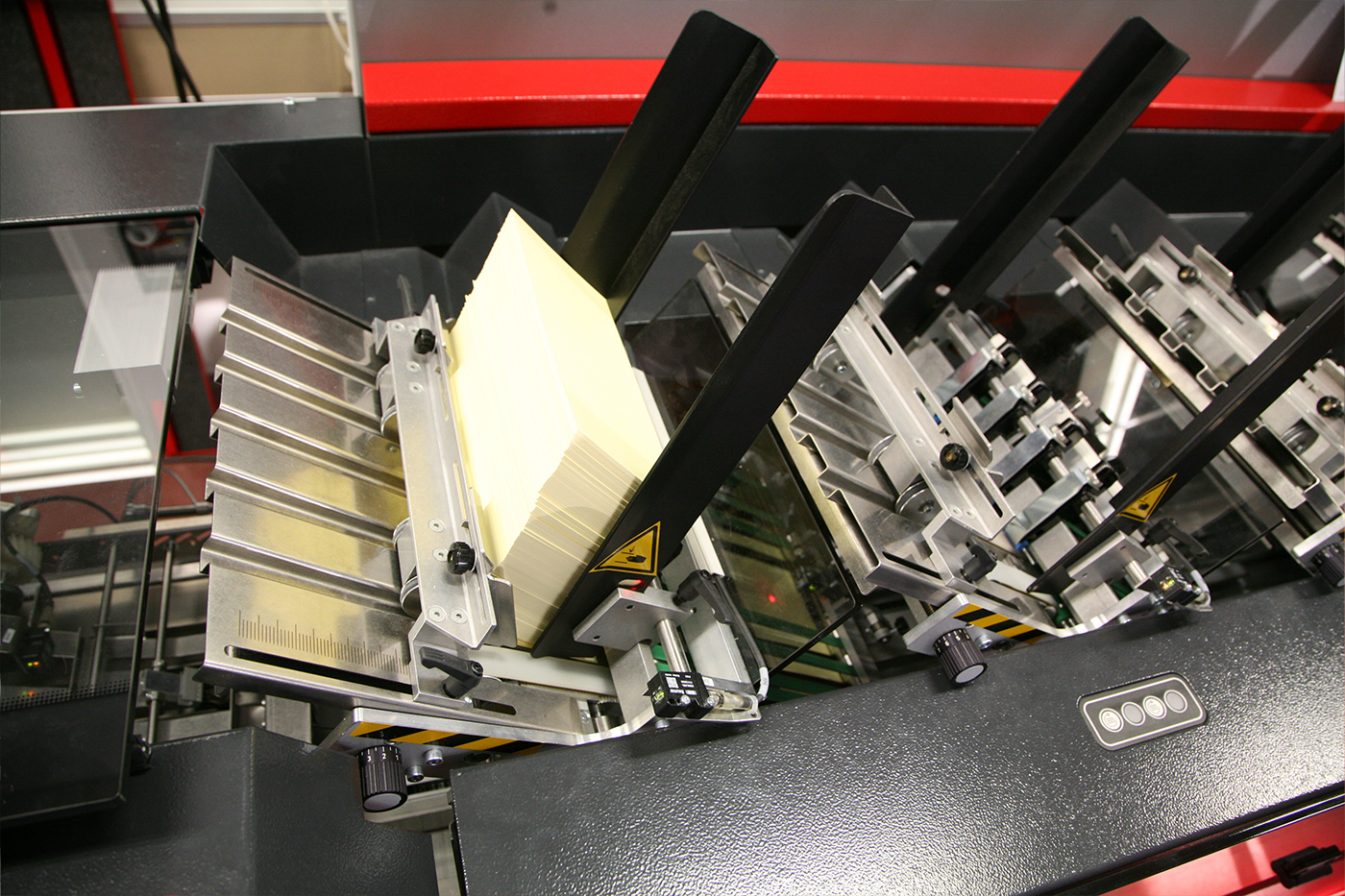

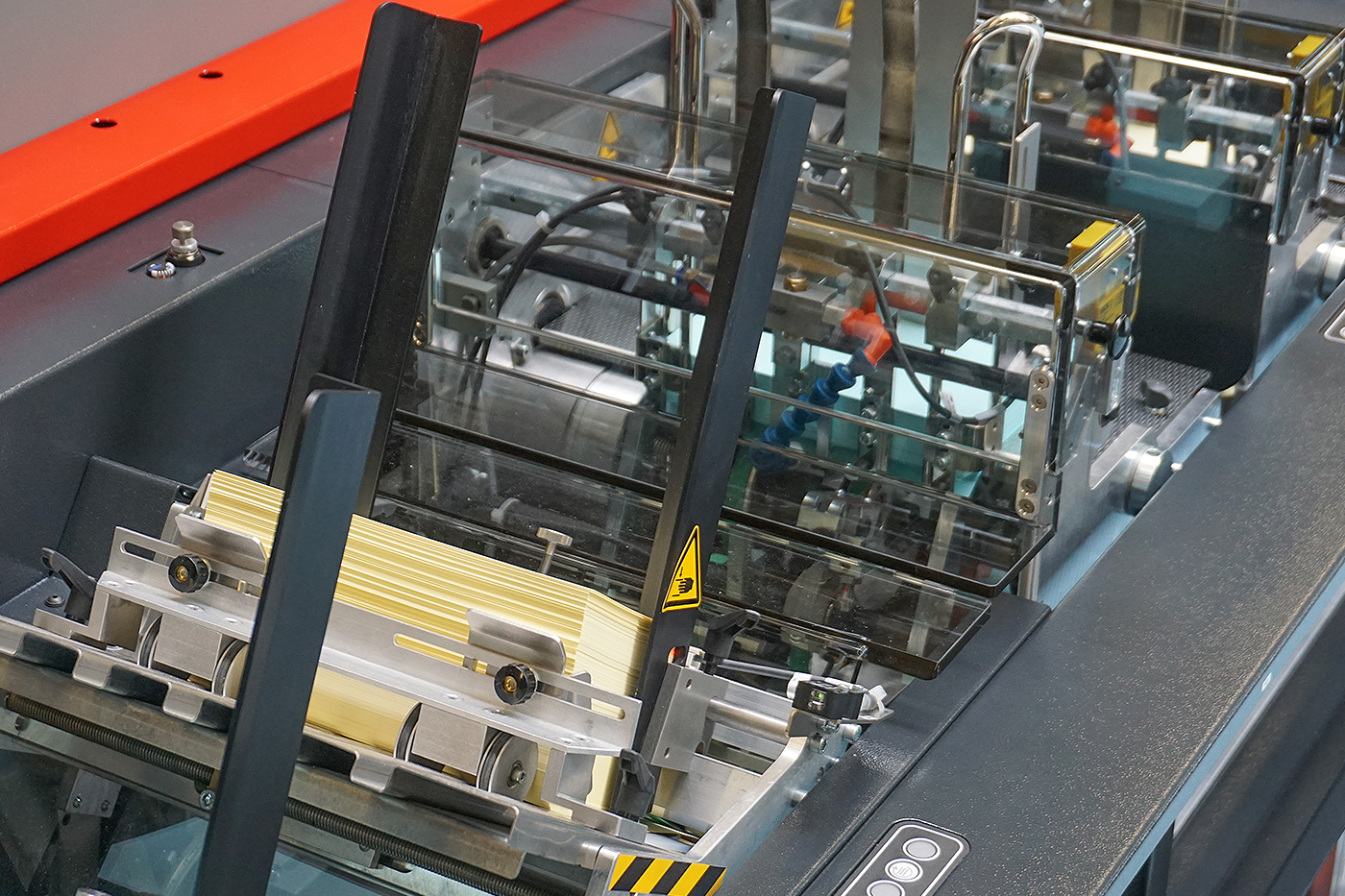

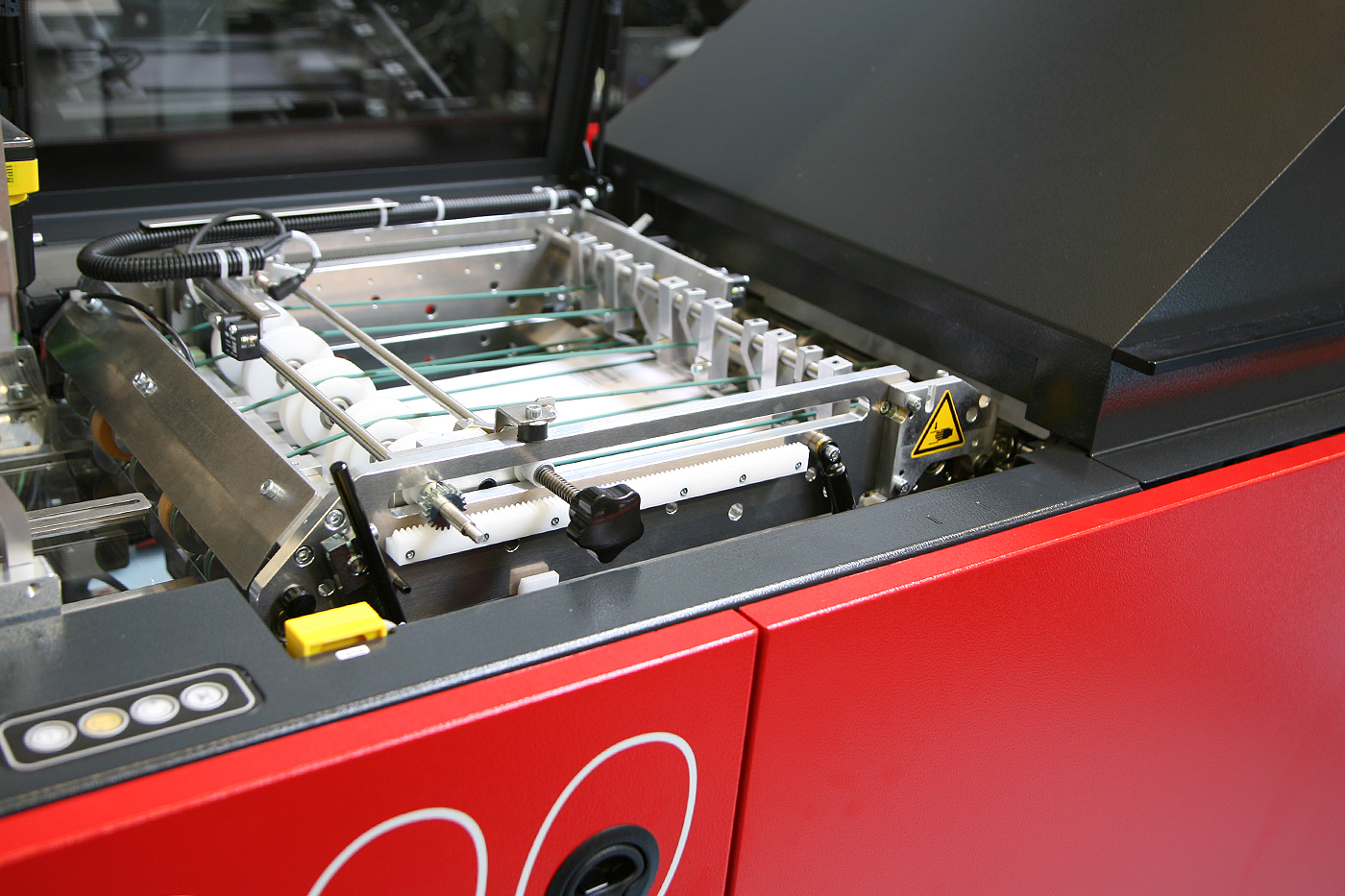

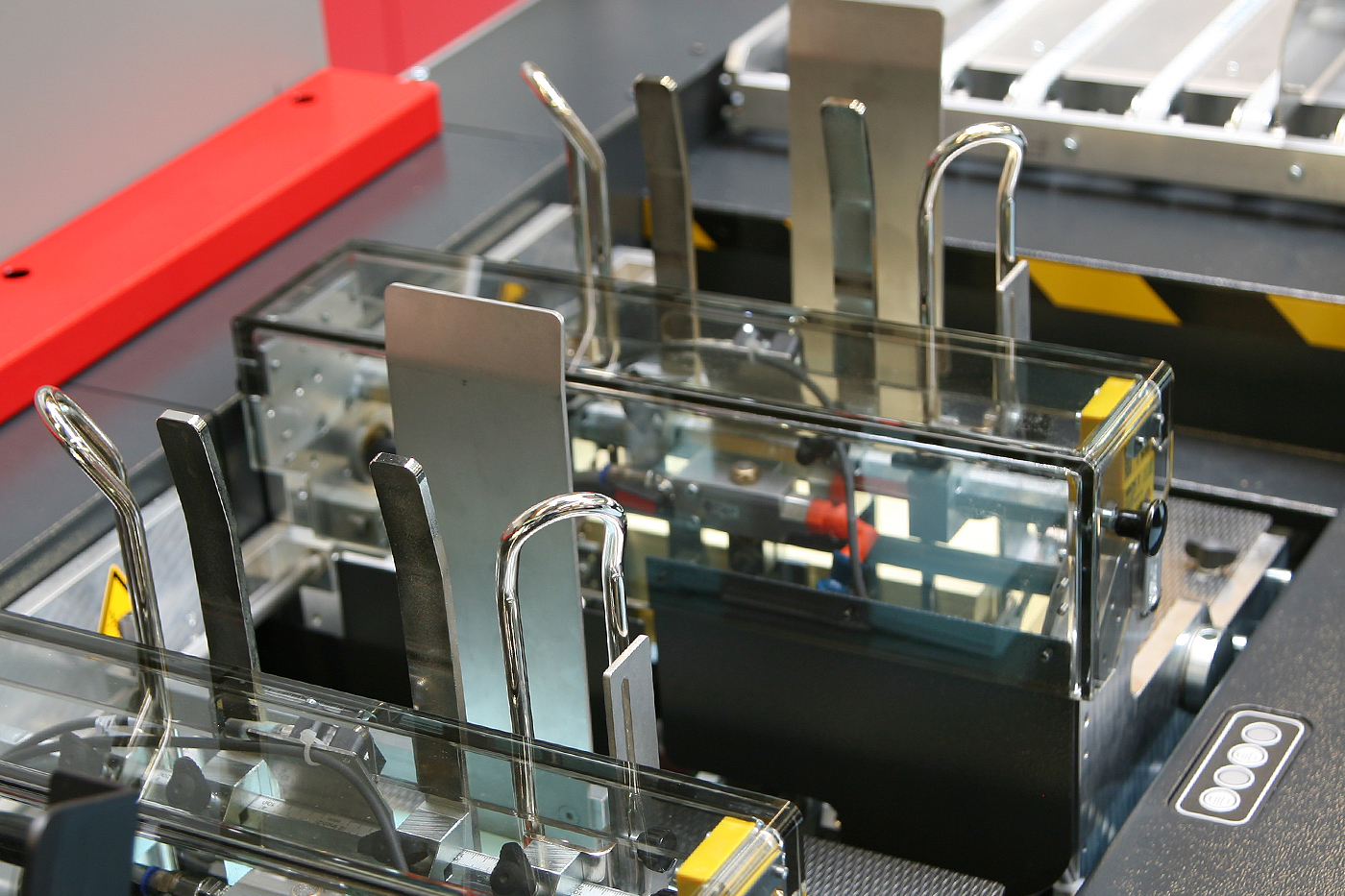

Up to 16 enclosure stations

The possibility of integrating up to 16 enclosure stations is particularly noteworthy. Friction feeders and rotary feeders can be combined. Thanks to the use of lamellas, there is no contact between the content and the envelope during the inserting process. This contactless inserting principle guarantees the highest reliability in the inserting process. The system can be equipped with automatic adjusting devices ex works on request. This means that the changeover can be reduced to a few manual operations by the operator. This very short changeover time and rapid availability for new jobs is a major advantage of the Kern 1600 flex.

Speed as a Service

In addition, customers can also book an upgrade at short-term notice in times of high-performance capacities, in the sense of "speed as a service", so that customers can be even more flexible with their Kern system in terms of processing. The system is controlled via a central touch panel. The necessary information is displayed to the operator in text and graphic form. At the machine output, the system can be equipped with the inkjet printing system Print@Exit. Like all the other systems in the Kern product family, the Kern 1600 flex can also be integrated into comprehensive workflow systems thanks to its complete ADF integration (mailFactory©).

Software system platform sphera

Kern Sphera Software offers you individually tailored software solutions in the area of ADF. Today’s organizations require not only high output rates, but must consider other critical production aspects such as processing security, and efficient overall productivity with high quality and low costs. The Kern Sphera Software products meet precisely these requirements. Vast amounts of data are required for production tracking, measurement, analysis, and improvement in the document output management area. In addition it must be available and accessible at all times. To simplify such a demanding installation, Kern Sphera Software draws on the cloud. This has the advantage of a high availability infrastructure as well as transparent, monthly costs.

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Kern system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you.

Get in contact