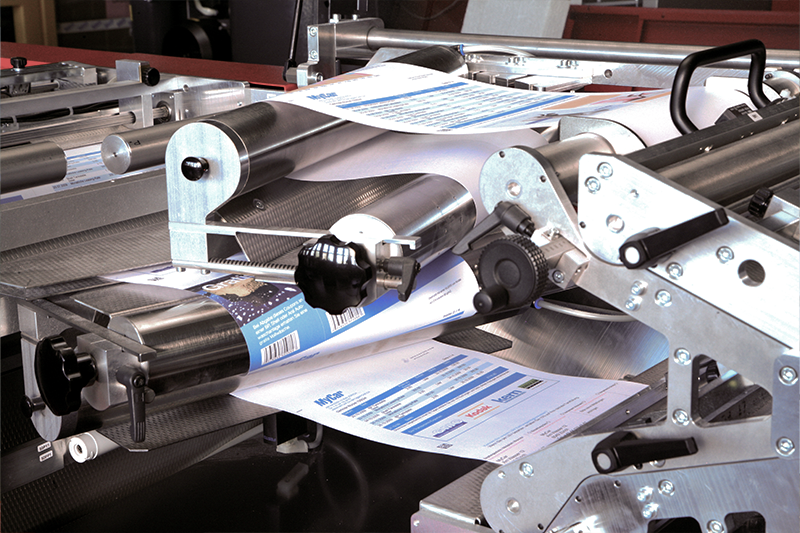

The cutting system Kern 996 processes a wide range of applications, offers great flexibility and is highly efficient. The Kern 972 single sheet feeder guarantees a high feeding capacity and ensures processing of up to 45,000 sheets per hour. The full capacity of the fast Kern inserting systems is thus optimally utilized.

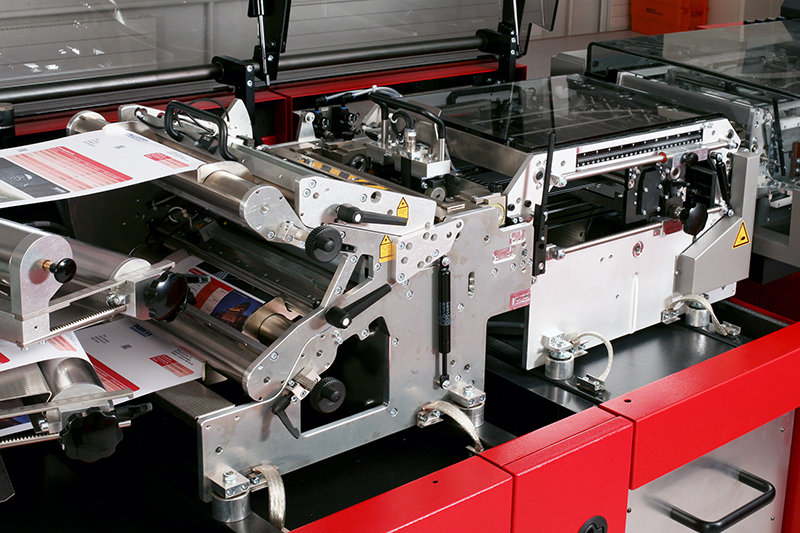

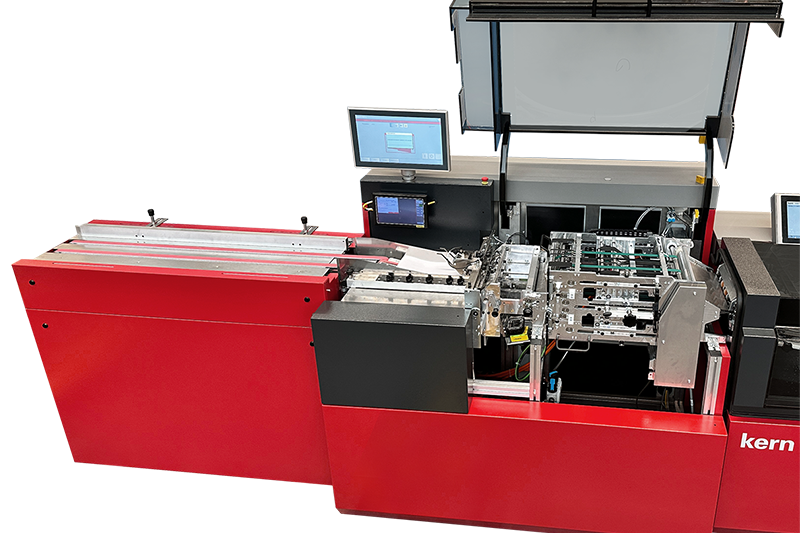

Kern 996 cutting system

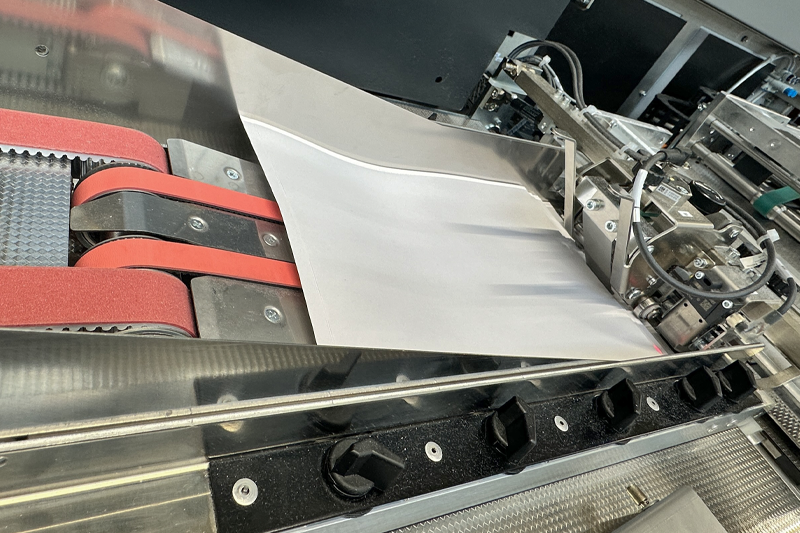

Efficient feed module – the cutter Kern 996 processes a wide variety of applications, offers great flexibility, and boasts high performance efficiency. The ergonomic design and the touch screen interface allow fast system access. The automated paper feed accelerates the setup process. The paper flow is clearly visible and easily accessible, so adjustments take little time.

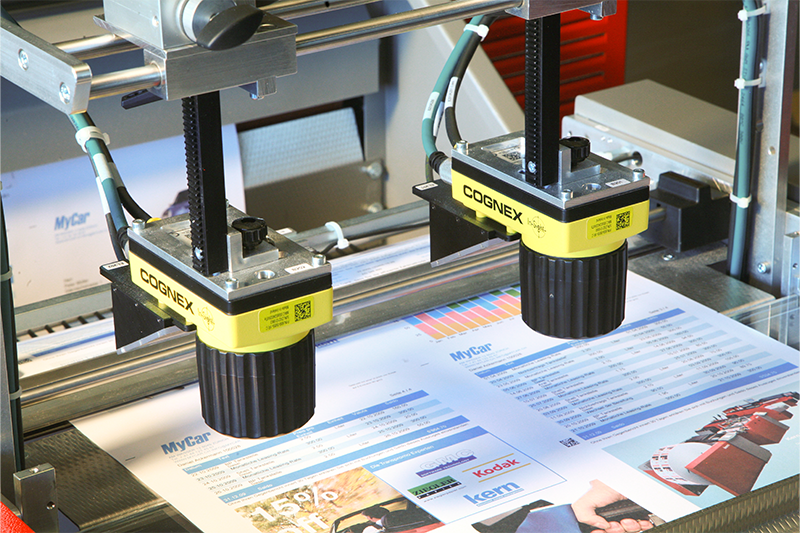

The paper transport is equipped for both pinless and pinfeed material. All common standard codes such as barcode, data matrix, OMR or OCR are processed reliably. The Kern 996 recognises and cuts out unprinted and unformatted ‘white’ zones (white paper) between two print jobs or in the event of interruptions. The GT grouping and deflection station deflects white, format and non-format documents.

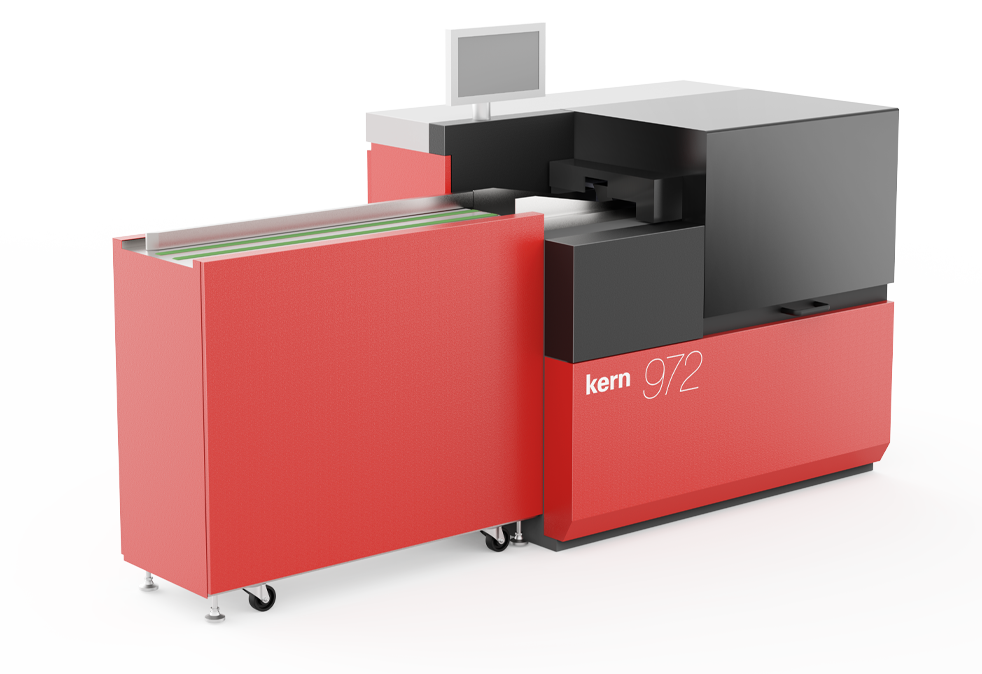

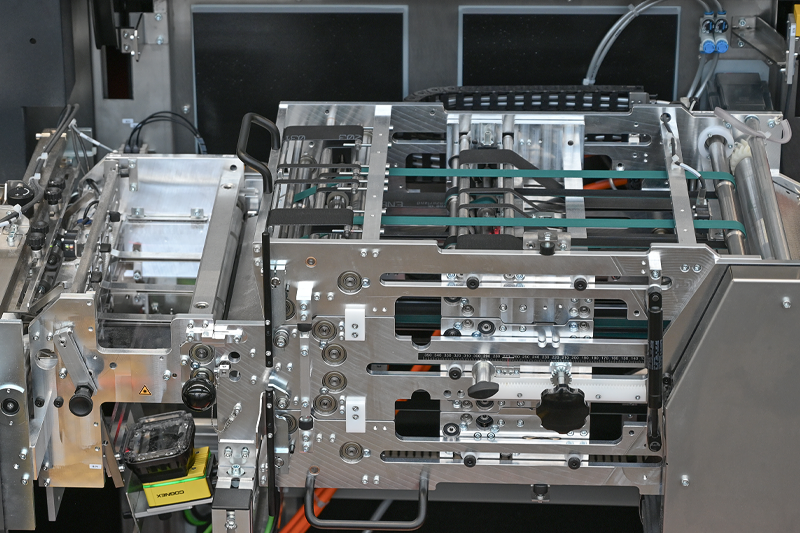

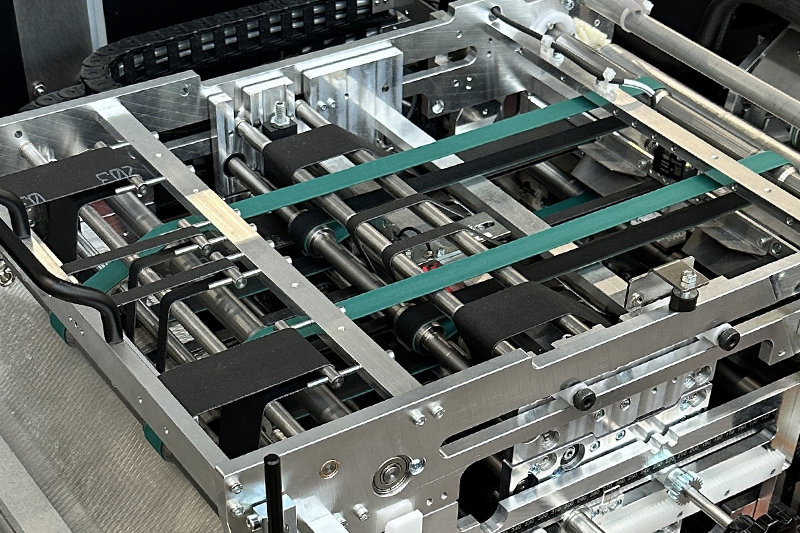

Kern 972 single sheet feeder

The high feeding capacity guarantees processing of up to 45,000 sheets per hour. This ensures that the full capacity of the fast Kern inserting systems is optimally utilized. During development, great importance was placed on a reduced noise level, which means that the machine works much more quietly and therefore provides a more pleasant working environment. The ergonomics of the Kern 972 have been optimized to make operation more comfortable and user-friendly. This contributes to better handling and increases user satisfaction.

Another key advantage of the Kern 972 is the optimized reading range, which functions independently of code and position. This improvement ensures even more precise and reliable data capture and processing. In addition, the Kern 972 cut sheet feeder can be fully integrated into the mailFactory®. This opens new opportunities and areas of application that simplify workflows and help to achieve the goals in the mailroom environment even more efficiently.

Software system platform sphera

Kern Sphera Software offers you individually tailored software solutions in the area of ADF. Today’s organizations require not only high output rates, but must consider other critical production aspects such as processing security, and efficient overall productivity with high quality and low costs.

The Kern Sphera Software products meet precisely these requirements. Vast amounts of data are required for production tracking, measurement, analysis, and improvement in the document output management area. In addition it must be available and accessible at all times. To simplify such a demanding installation, Kern Sphera Software draws on the cloud. This has the advantage of a high availability infrastructure as well as transparent, monthly costs.

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Kern system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

| Pure cutting performance at 12" | Max. 36‘000 cuts/h with single cut Max. 72‘000 documents/h Max. 32‘000 cuts/h with double cut 1/6" Max. 64‘000 documents/h |

| Pure cutting performance at 4" | Max. 55‘000 cuts/h with single cut Max. 110‘000 documents/h Max. 46‘000 cuts/h with double cut 1/6" Max. 92‘000 documents/h |

| Format width 1-up | 148–295 mm |

| Format width 2-up | 296–520 mm |

| Document length | 89–407 mm |

| Document transport: | Pinless |

| Compatible with |

|

| Document format | Length 203–356 mm Width 210–305 mm |

| Processing speed | Up to 45’000 documents/hour |

| Reading types | Barcode, OMR, Datamatrix (others on request) |

| Paper weight |

|

| Stack capacity | Max. 2'500 sheets |

| mailFactory® | Full integration into Kern mailFactory® |

| Compatible with |

|

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you.

Get in contact![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/02-Systeme-Loesungen/Kern_Eingabemodule/Kern_972/Kern_972_-_Foto_01small.png)