For over seven decades, Kern has stood for high innovation capability, quality, flexibility and reliability. Factors that, above all, entitle for the highest attainable level of safety and service.

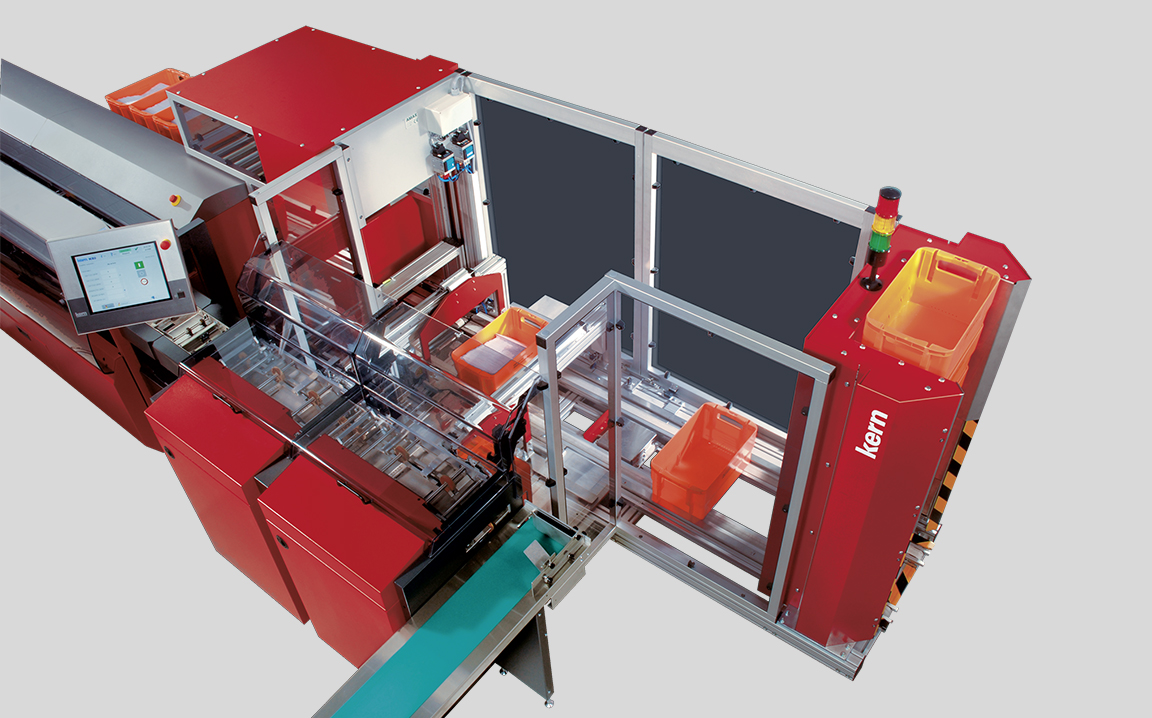

The most recent packaging solution development is the PackOnTime 2box multi-format packaging system. This operates with sustainable recycled cardboard, and makes the need for additional filling materials (such as plastic, bubble wrap, polystyrene, and so on) redundant. Orders of all kinds (single and multiple items) are measured in 3D, and then inserted into the precisely tailored packaging.

This arises on the one hand from the flexible production planning and process control, and on the other, from a long-standing and highly qualified team of development specialists.

The Group operates in around 50 countries worldwide and employs about 500 people. Kern Service is available, worldwide, 365 days a year: for optimum system availability and productivity, Kern offers a comprehensive and reliable service portfolio.

Kern experts and Kern partners will be happy to answer questions and provide information on individual products. Reliable service is one of the most significant building blocks of our company. For optimal system availability and productivity, Kern AG offers a comprehensive and reliable service programme.

Do you require advice and support on an inserting process or the Kern mailFactory® software? Or maybe you have other questions regarding the mailing process, or would like to send us your suggestions or requests? We will be happy to assist you and draw up a personalised quote!

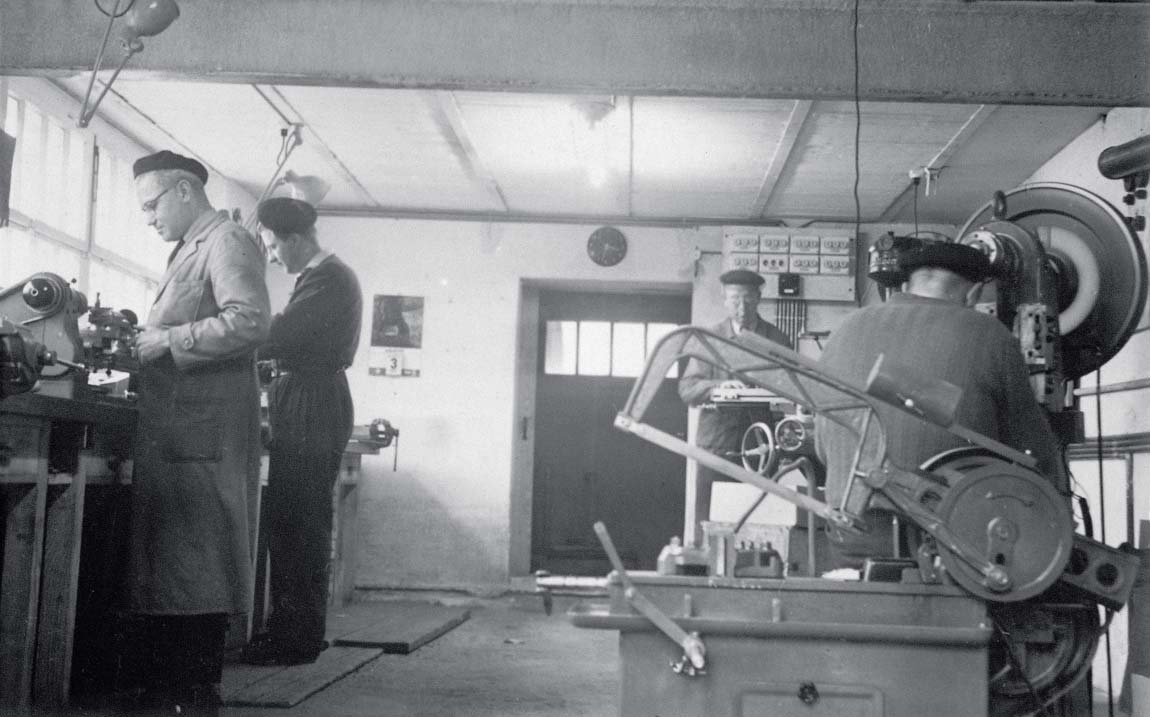

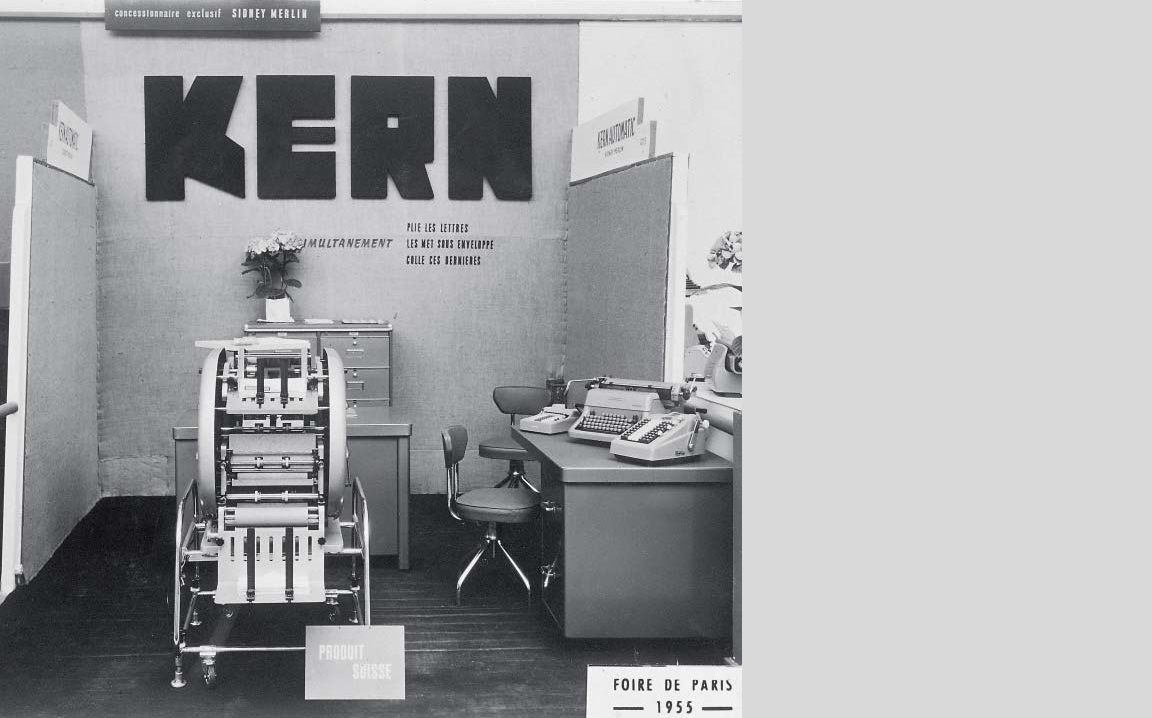

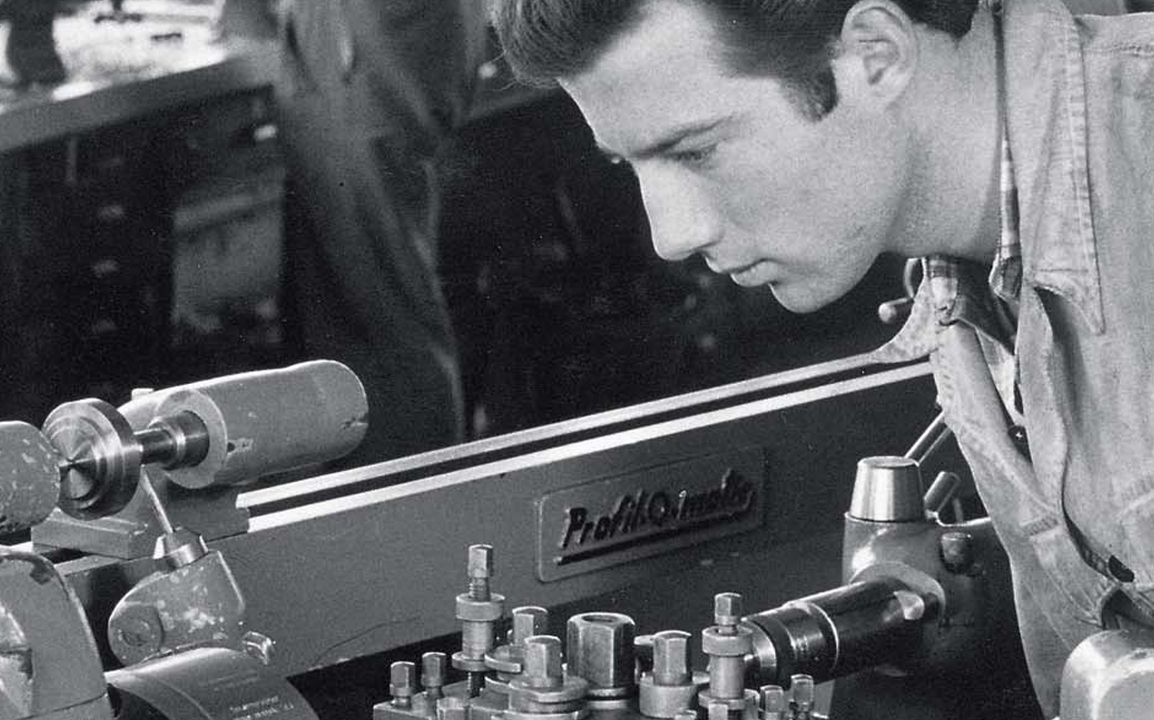

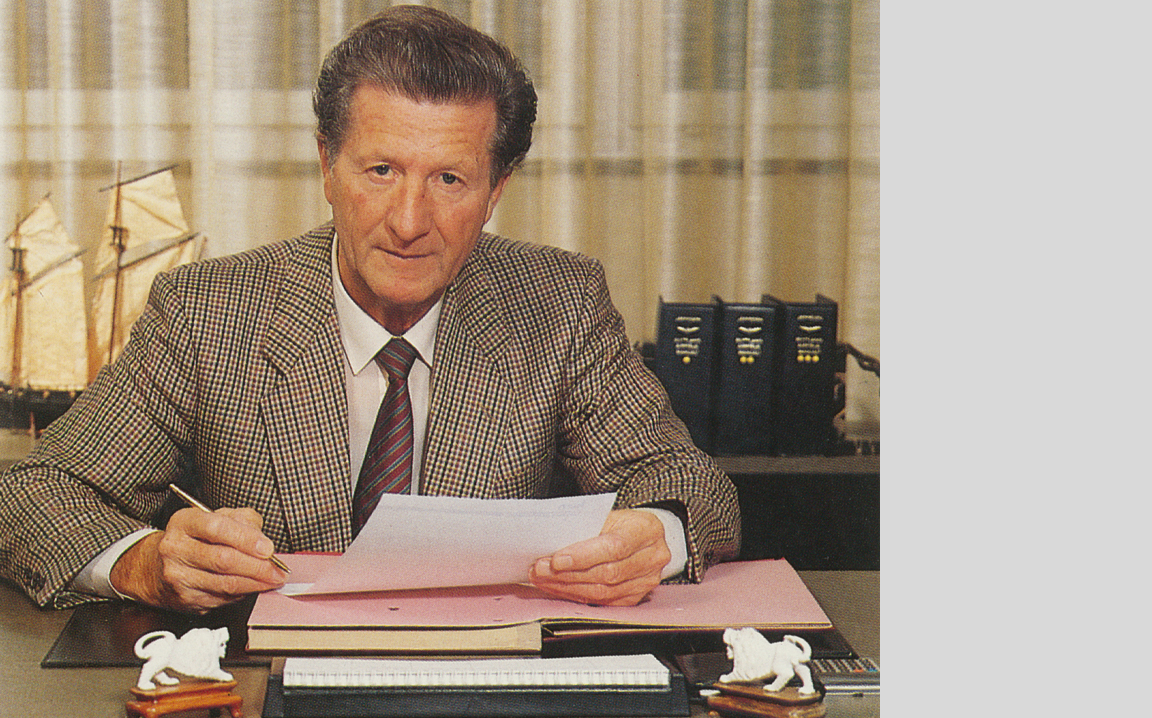

Since it was founded by Marc Kern in 1947, the company has remained within the family. With its roots in Konolfingen in Bern, Switzerland, of the Swiss company’s fame quickly spread beyond national borders.

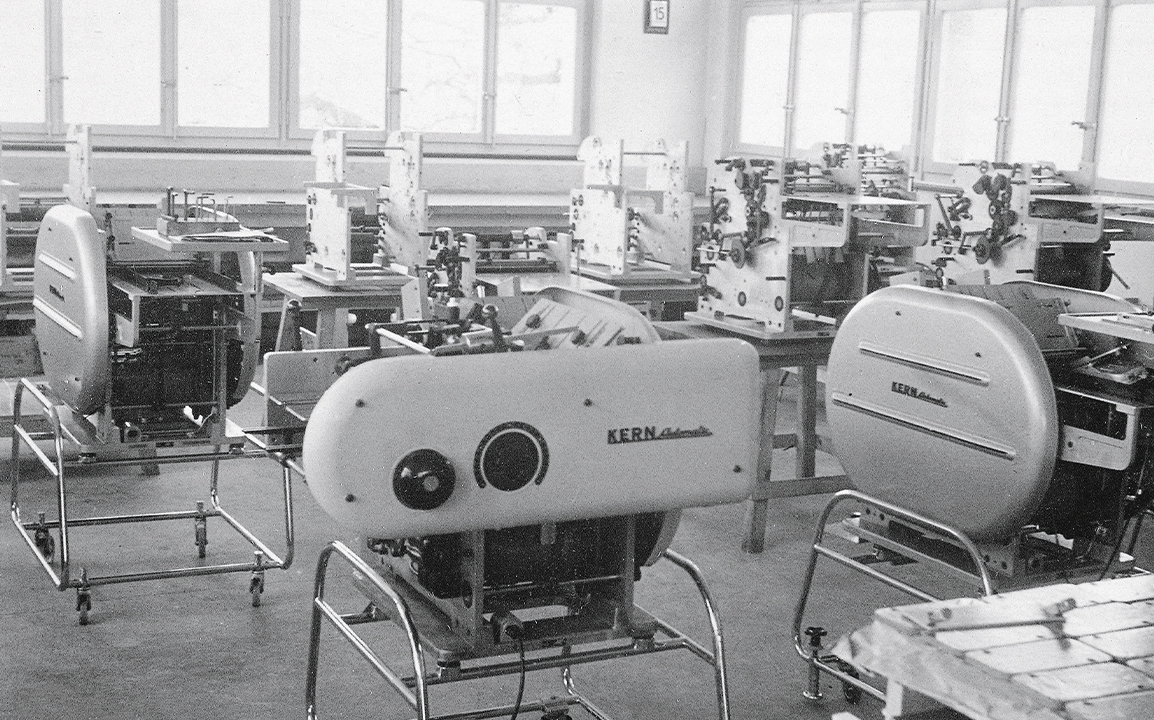

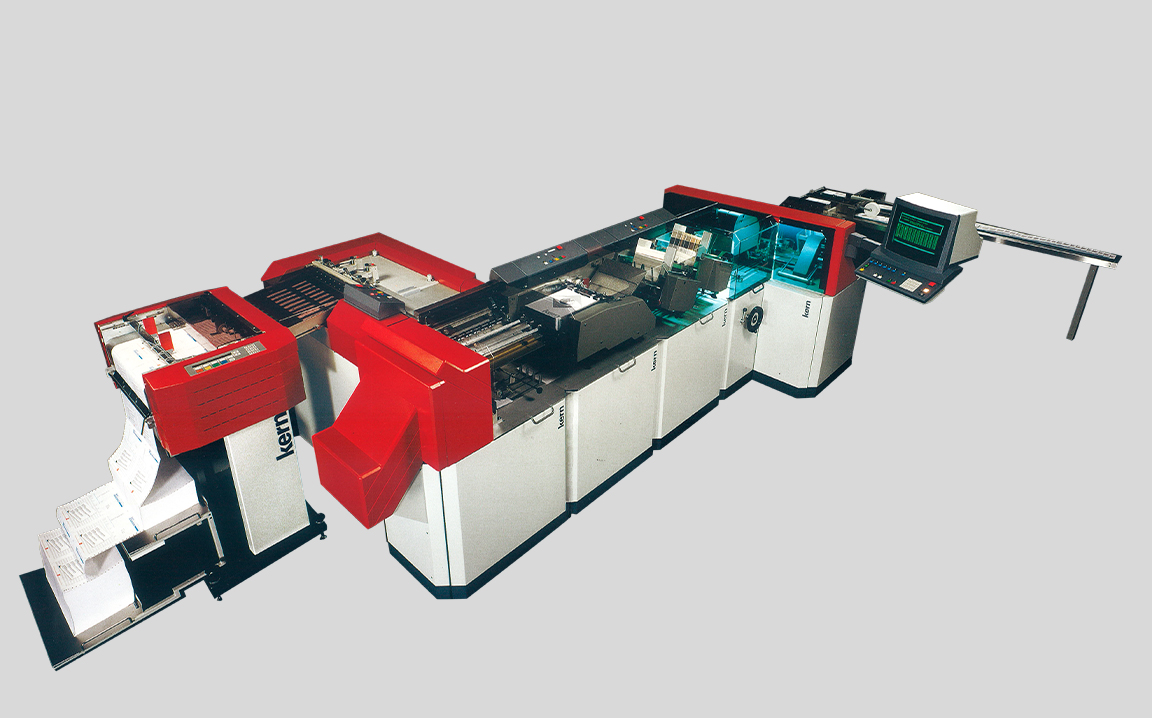

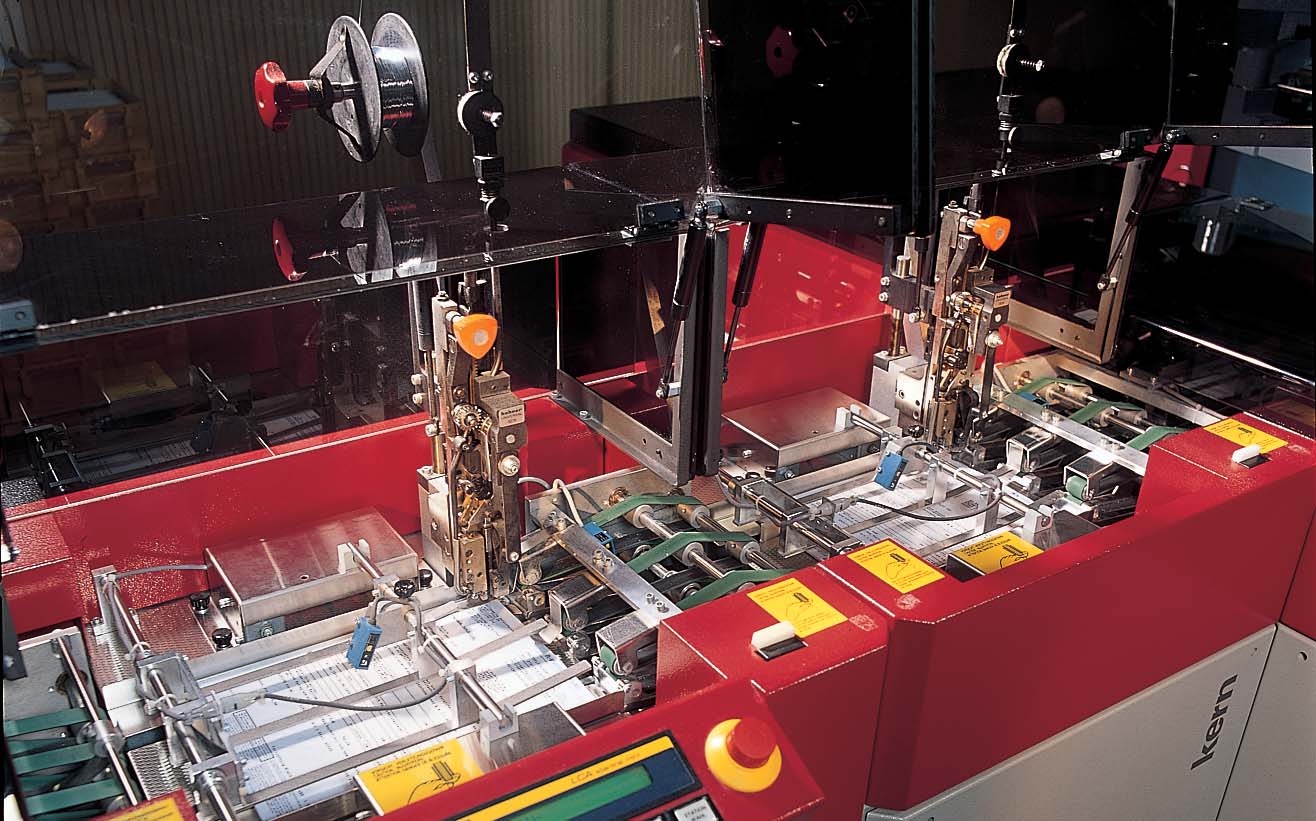

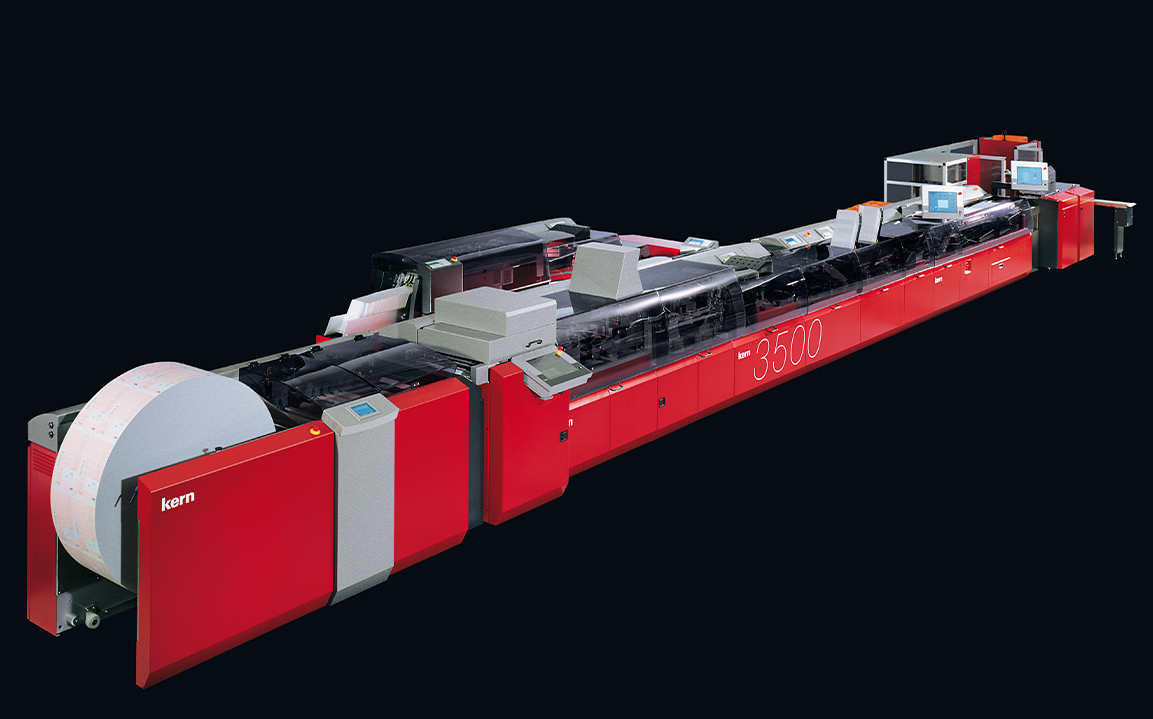

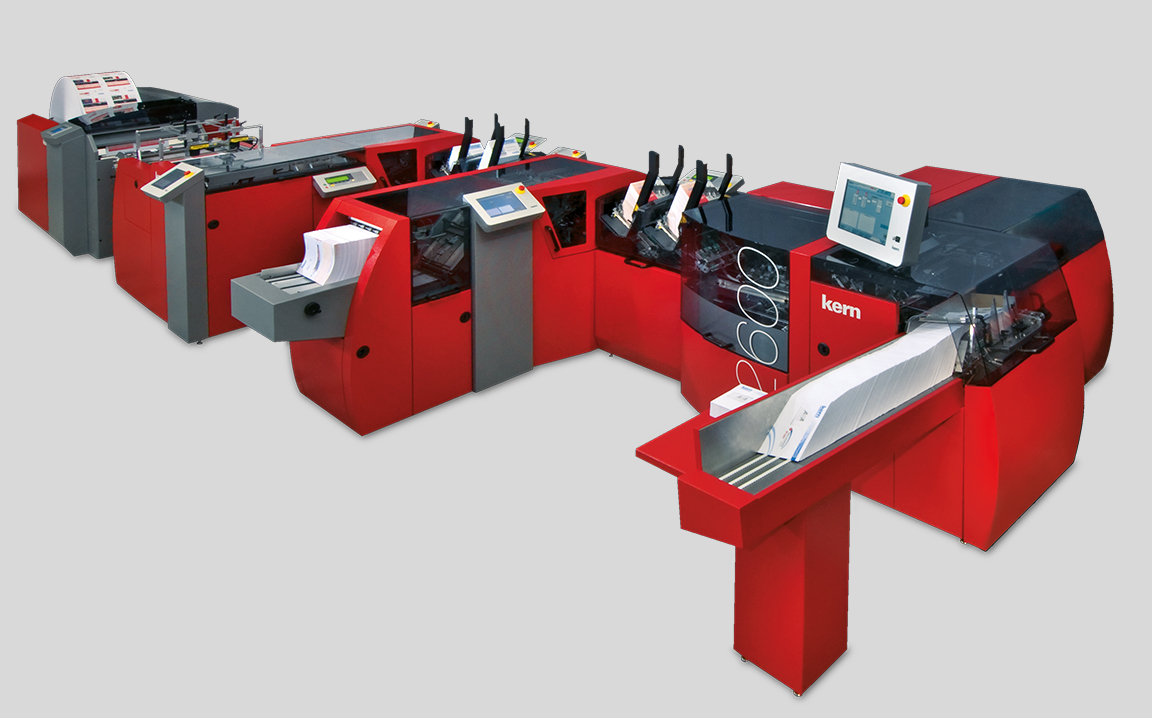

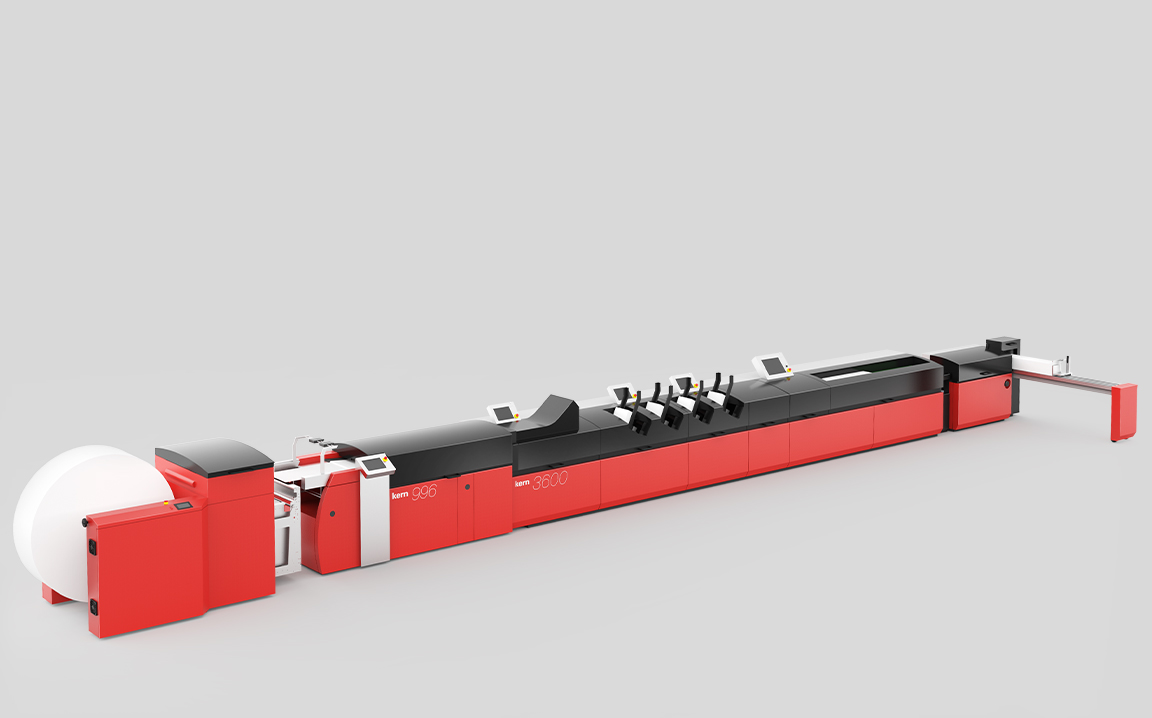

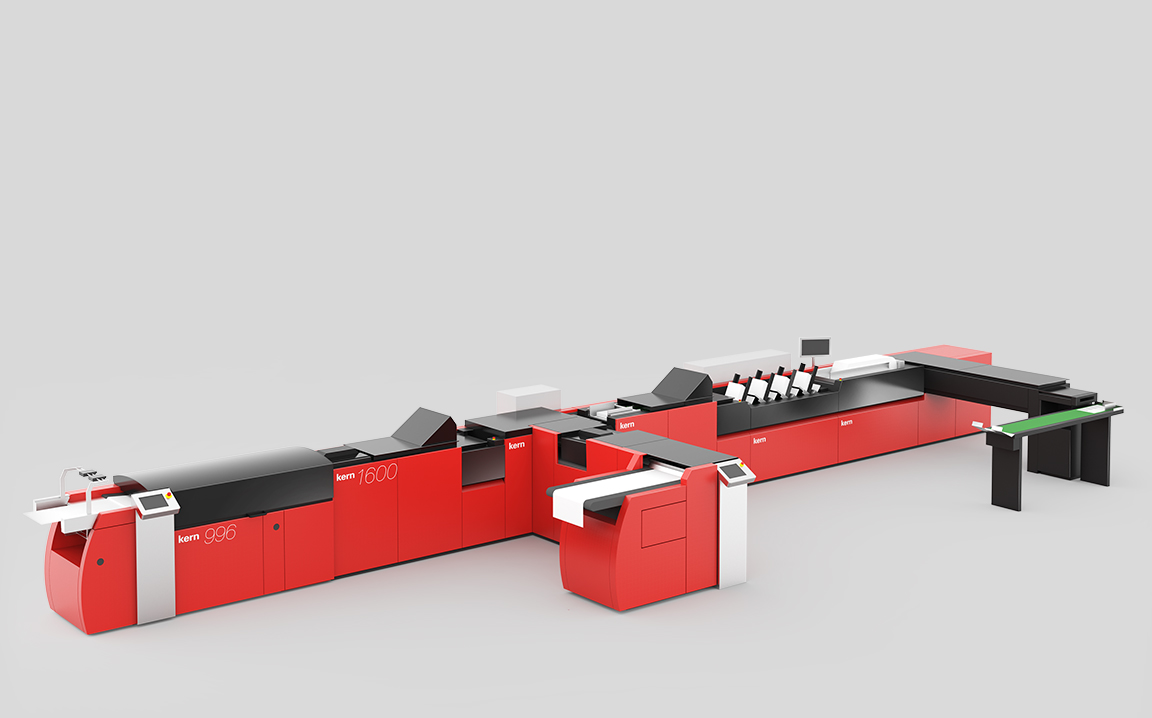

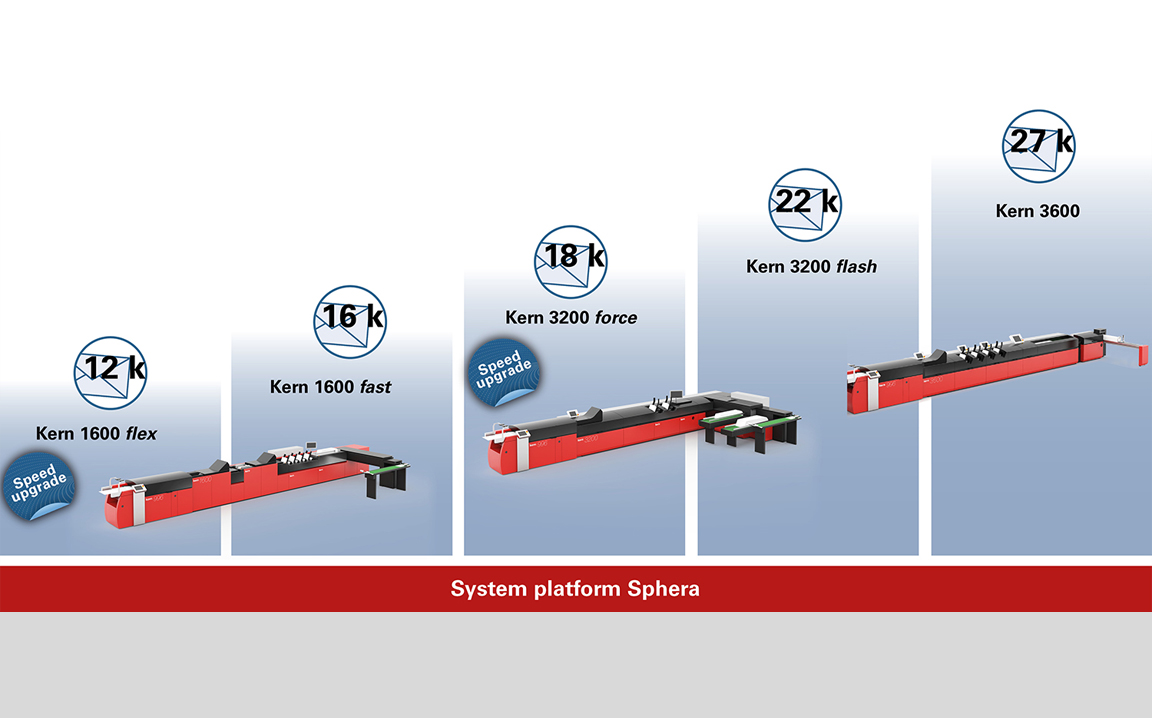

Since then, Kern has put a great deal of energy into developing and implementing new ideas. Whether for optical reading and on-line processing in the 1960s, modular mailing systems in the 1980s, the Kern 3000 – the fastest inserting system in the world – in the 1990s, or the development of sophisticated robots in the new century. Kern again and again opened up new horizons in document processing and packaging. This development has resulted in steady growth and sustained success.

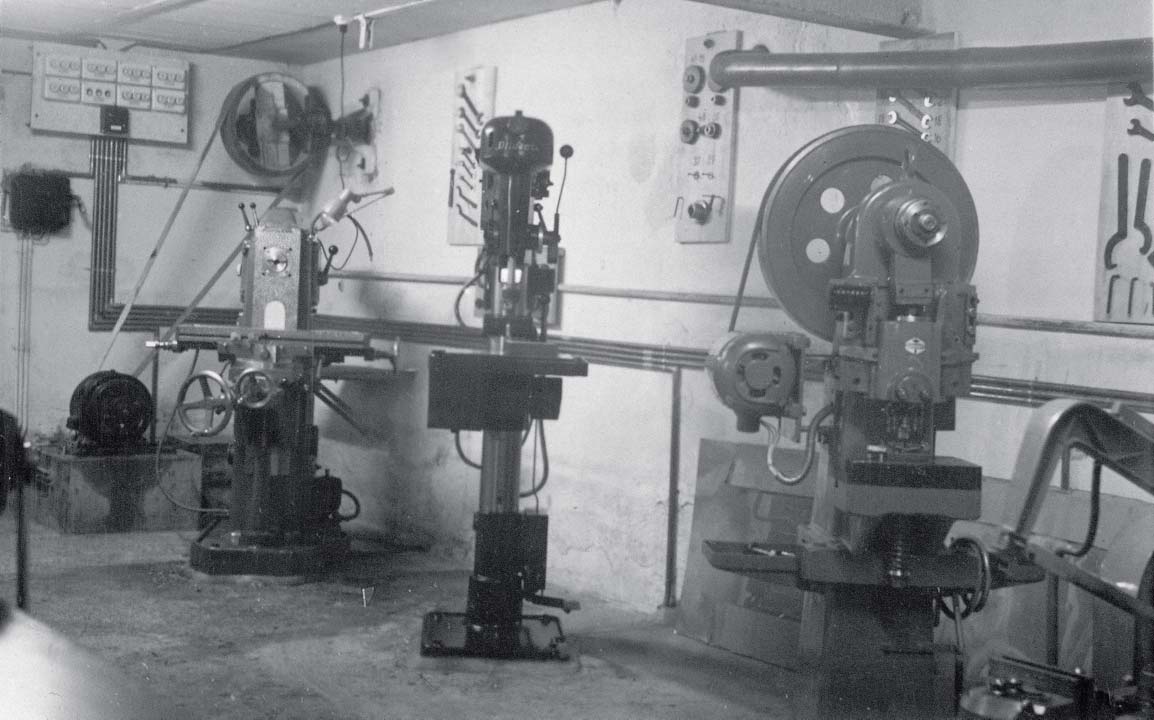

The first building for a larger production workshop is built on Hünigenstrasse in Konolfingen. Production of the first enveloping machine. The Kern company is converted into a public limited company. Marc Kern becomes the sole shareholder. The aim of the new inserting machine (Kern Automatic) is to reliably process one envelope per second. An electronics laboratory is set up in Konolfingen. The world's first folding inserting systems with optical mark reading under the name KAE (Kern Automatic Electronic) leave the factory in Hünigenstrasse. Manufacturer Marc Kern is proud of his latest product. The factory in Konolfingen is expanded to meet the growing demand for Kern machines.

Be it optical reading and online processing in the 1960s, modular mailing systems in the 1980s, the fastest inserting system in the world in the 1990s (Kern 3000) or the development of sophisticated robots in the new millennium. Kern AG repeatedly opened up new dimensions in document processing and packaging. Ongoing growth and continued success were the results of this development.

75 years of Kern AG. Kern enters the next generation of inserting technology with the Kern 3200. Launch of a new product in the packaging solutions division: Multi-format packaging system for the production of customised corrugated cardboard packages in real time. Kern Group repositions itself for the future: Personnel and structural reorganisation at all levels.

As a family business, we place the highest value on the health and safety of our employees. We consistently focus on prevention and ensure that applicable safety rules are observed and actively practised at all locations. To promote environmentally friendly mobility, electric vehicles are part of the company car fleet of our sales representatives. Our integrated management system has been certified in accordance with ISO 9001:2015 (quality management) and ISO 14001:2015 (environmental management) since 2022 - a clear commitment to quality, climate protection and sustainable development.

| WEConnect International | WEConnect International is a leading global nonprofit dedicated to economically empowering women business owners by connecting them with large corporations, multilateral organizations, and government buyers worldwide. |

| Zertifikat ISO 9001:2015 | ISO 9001:2015 is an internationally recognized standard for quality management systems (QMS). It provides a framework for companies to structure their processes and increase customer satisfaction by meeting customer and regulatory requirements. The standard focuses on risk-based thinking, the process approach and continuous improvement. |

| Zertifikat ISO 14001:2015 | The international environmental management standard ISO 14001 defines globally recognized requirements for an environmental management system. For Kern, an environmentally conscious contribution to a sustainable future is very important. |

| Green energy certificate | Kern AG consciously favours 100 % renewable energy from ecological production - certified with the renowned naturemade star seal of quality. In this way, we ensure that our electricity meets the highest environmental standards and makes a real contribution to climate protection. |

| Safety Charta | In Switzerland, around 250,000 work-related accidents are caused every year. The safety charta aims to reduce this high number by improving safety at work. Launched by Suva in collaboration with employee associations, planners and trade unions, it represents a willingness on the part of all its signatories to consistently comply with and enforce the vital essential rules in the workplace. The motto is "Stop at danger!" is a commitment, because no work is so important that one's own health or that of employees is endangered. |

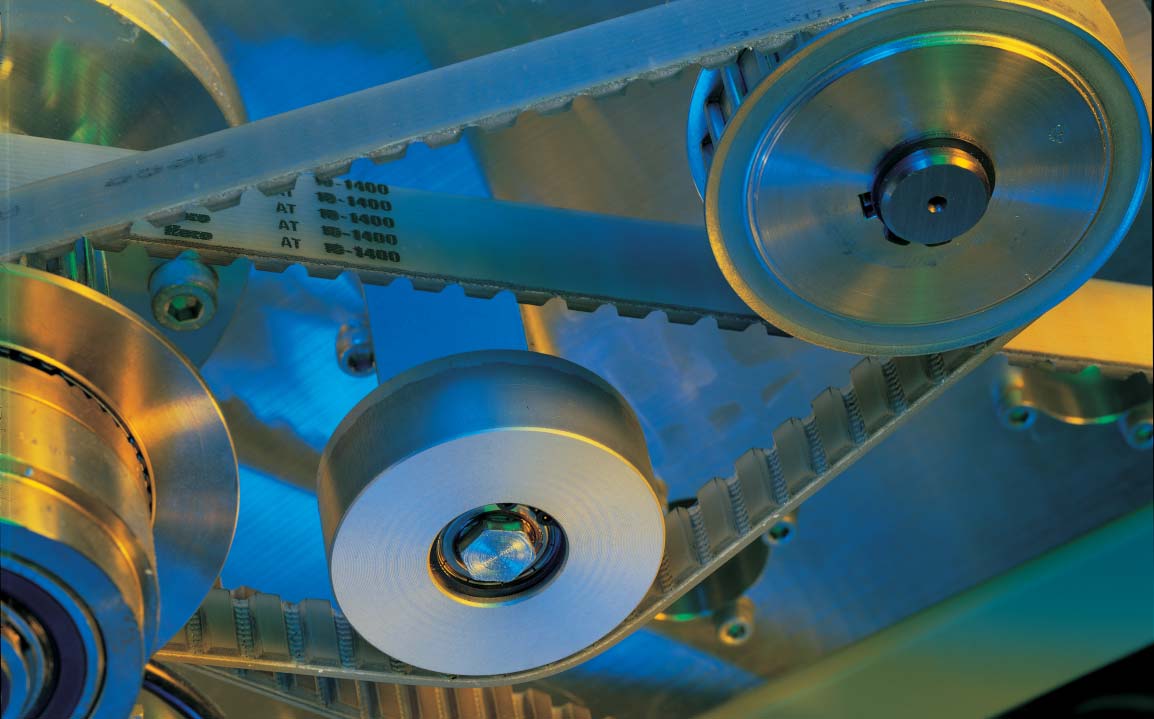

Kern AG consistently invests in quality... a trademark of Kern AG for years. Kern systems are known for their durability and high-precision workmanship. The fact that Kern AG has been ISO certified for many years is fundamental proof of this. This means that customers can also guarantee perfect in-house production.

| Research and Development | Customer needs are the starting point for new ideas and technologies. Highly qualified specialists develop solutions for future technologies and processes that simplify workflows and meet customer expectations. Kern is always ahead of the state of the art and sets international standards for innovation – thanks to its own development department in Switzerland. |

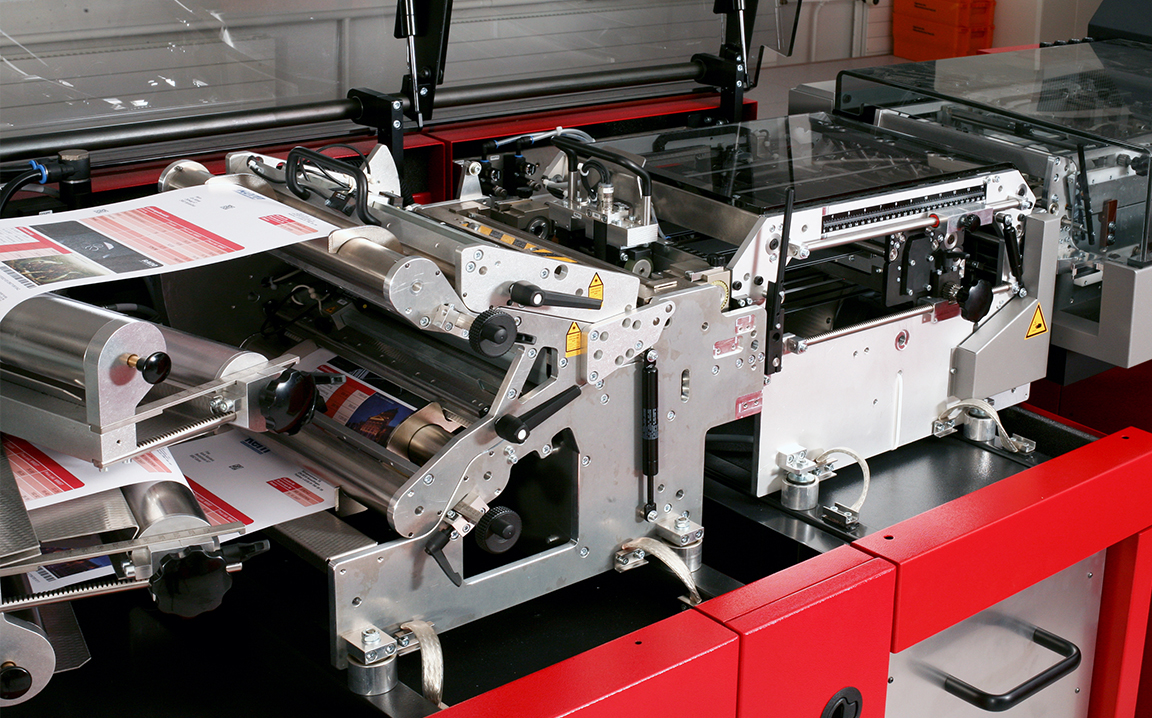

| Specialist in Production and Assembly | Quality awareness shapes all production and assembly processes. The inserting and packaging systems are developed in Switzerland and manufactured according to the highest standards of Switzerland and the EU. Qualified personnel handle the technical implementation – whether it is a cutting machine or a complex packaging system. Short decision-making paths and state-of-the-art technology ensure efficient and on-time processes. |

| With Kern’s leading technology, you are ahead. | Kern is a leading partner in document processing – from complete packaging installations to individual modules. The goal is to provide customers with reliable, future-oriented solutions that deliver top performance in operation. Precise technology, intelligent software, and thoughtful design are key quality features. Numerous awards in industrial design and important certificates such as ISO confirm the high quality. Kern continuously develops to remain a market leader – committed to tradition. |

| Certificates ISO 9001:2015 and 14001:2015 | ISO 9001 defines the requirements for a quality management system that ensures products and services meet customer expectations as well as regulatory requirements. At the same time, the system is intended to undergo continuous improvement. ISO 14001:2015 specifies the requirements for an environmental management system through which an organization controls and continuously reduces its environmental impact. |